With the rapid developments of 3D printing and robotics one had to suspect that it was only a matter of time before a house was digitally fabricated. That time is now.

Enter the DFAB House Project of Switzerland. The world’s first building to be designed, planned and built using predominantly digital processes. The DFAB House is a National Centre of Competence in Research (NCCR) Digital Fabrication, architects, robotics specialists, material scientists, structural engineers and sustainability experts from ETH Zurich project, which is taking place at the NEST campus in Dübendorf.

The thing that sets the DFAB House apart from other prefab houses is that it was designed and planned digitally but it is also built predominantly through a digital process. Individually, the components were digitally coordinated and were manufactured based on the design, directly from this data. Come the summer of 2018 this three storey DFAB House will become residence and working space for guest researchers.

According to the DFAB House website this project puts four new building methods to the test. For this post, I am only going to wade into two of them.

Smart Dynamic Casting

Smart Dynamic Casting or SDC, is basically slip forming except this slip forming is done by robotics. According to the DFAB House people this process allows for the removal of individual made formwork for the construction of complex concrete structures. The automation through robotics certainly simplifies the slip forming process as it requires one worker to push a few buttons instead of several workers to maintain the pour.

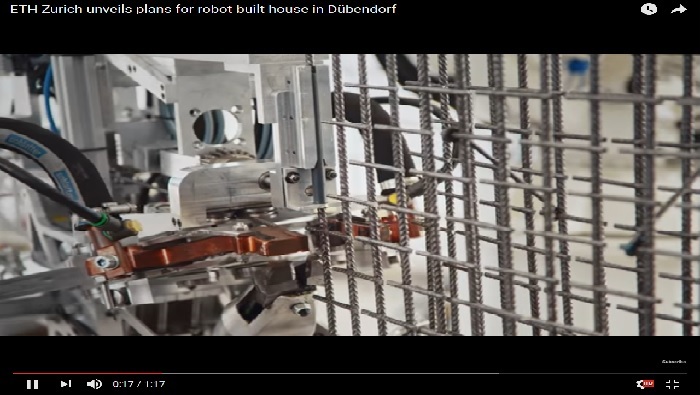

Mesh Mould

Mesh Mould allows for the combination of form work and reinforcement through robotics to create fully load bearing, non-standard concrete constructions. Traditionally, most reinforced concrete constructs utilize standard shapes due the complexity of other geometric shapes requiring expensive, one off, customized formwork. Mesh Mould solves those monetary restrictions on non-standard architecture in reinforced concrete. More complex shapes, greatly reduced formwork waste and an automated process freeing up man hours, what’s not to love?

While all of these new building processes work wonders in the laboratory, it may be some time yet before we see these breakthroughs in reinforced concrete constructions on the job site. But, just like 3D printed houses that were once built only in laboratory settings, these techniques can’t be too far off from a construction site near you.